Artificial intelligence (AI) and robotics are different disciplines, however, they can benefit each other and coexist. AI in robotics is vital to help robots perform important tasks, some of which are very repetitive and can lead to errors when done by humans.

Modern robots use machine learning training and a huge number of datasets to train computer vision models that allow them to recognize objects and complete their tasks. Sensors use a variety of data for perception and awareness, whether it’s in agriculture or in smart homes, to continuously improve processes.

In this article, we’ll look at a few use cases of AI in robotics in:

- Healthcare

- Space exploration

- Manufacturing

- Agriculture

- Smart homes

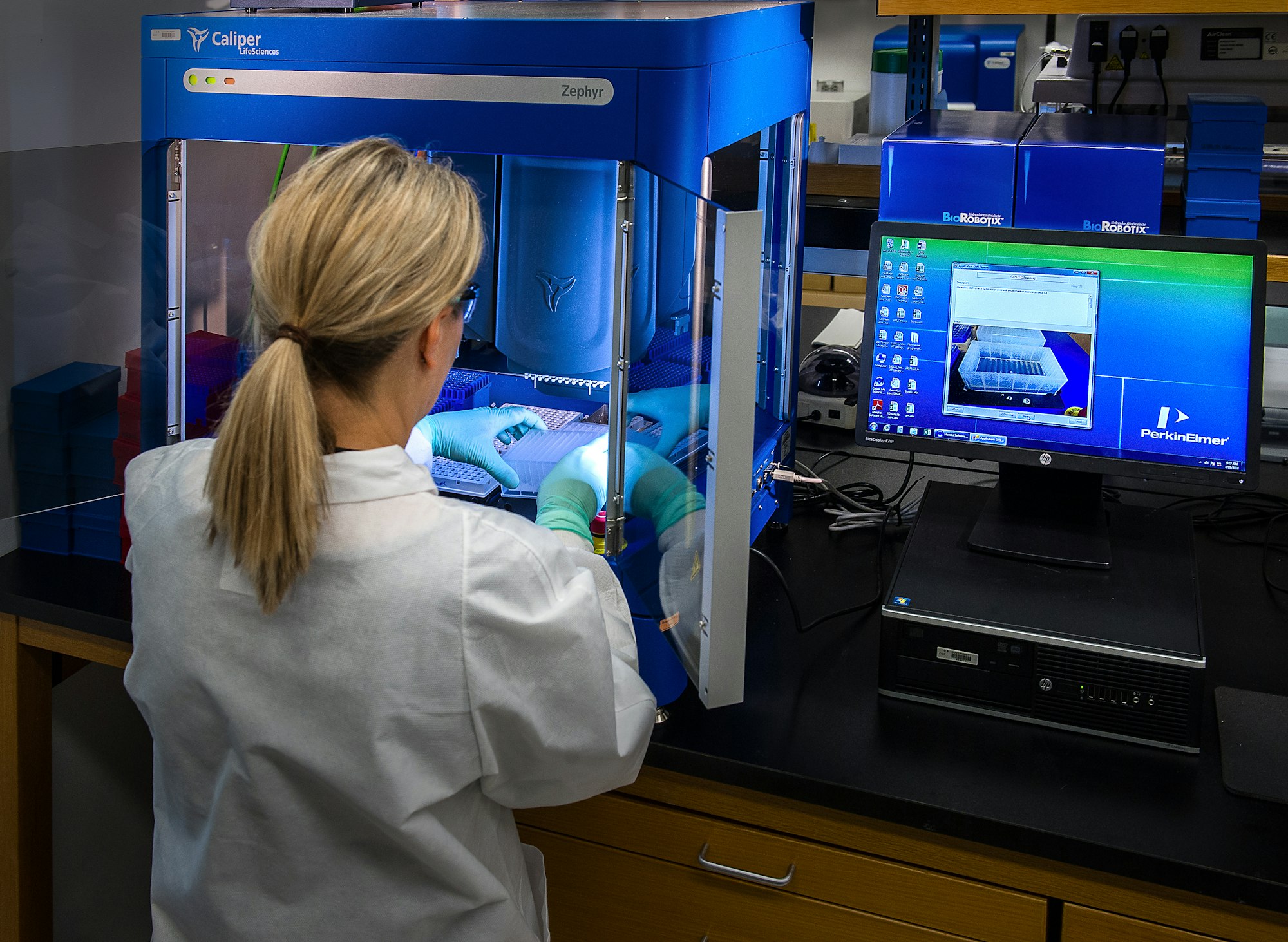

Robotics in healthcare

Whether it’s autonomous blood drawing devices or robot arms being used in surgeries, robotics in healthcare helps to fill in any gaps in healthcare that employees struggle to address. Robotics can also help make processes more efficient, offer a high level of patient care, and aid in providing a safe environment for both patients and healthcare workers.

Service robots can transport linens and supplies in healthcare environments, being especially useful when pathogen exposure is a risk for workers. Hospital-acquired infections are a big issue, with 1 in 25 US hospital patients being diagnosed with at least one infection every year, and cleaning and disinfection robots can both limit exposure and help to reduce these infections.

Robotic assistants also help perform surgeries, such as orthopedic and minimally invasive torso surgeries. With orthopedic surgeries, the Mako robot from Stryker is pre-programmed to help in hip and knee replacements. It combines 3D imaging, smart robotic arms, and data analytics to provide more predictable results, using spatially defined boundaries to assist the surgeons.

With minimally invasive torso surgeries, such as bariatric surgery and robotic hysterectomy, robots are inserted through a small incision, locking themselves in place and creating a stable platform for remote control surgeries. The da Vinci Robot from Intuitive aims at making procedures easy and accurate, helping to reduce both infections and other complications.

Take a deeper dive at the role of AI in healthcare below:

Robotics in space exploration

CIMON-2 from Airbus has been used on the International Space Station (ISS) for its autonomous flight capabilities, ability to understand and complete tasks, and voice-controlled navigation. It’s designed to help astronauts reduce their stress levels and complete day-to-day tasks, while also being an early-warning system.

iSpace’s unmanned rover is designed for surface exploration, but its team also plans for its potential future use in building the first shelters on the moon. The rover is shaped like a metallic beetle, weighs 3.7kg, and is equipped with 360-degree view 3D cameras. It can also wield tools like manipulators and drills to extract resources and build shelters on zero-gravity ground.

NASA’s R5, also known as Valkyrie, was initially built by the Johnson Space Center (JSC) for the 2013 DARPA Robotics Challenge (DRC). This six-foot-tall, 132kg humanoid robot is designed to help astronauts in various tasks while in space. Valkyrie has multiple actuators that allow for 44 degrees of freedom, it’s entirely powered by a battery, has gripper hands, and cameras and sensors on the chest and head.

NASA is also working on a robotic spacecraft, Restore-L, which is equipped with technologies, tools, and techniques to expand the lifespan of in situ satellites. Equipped with an autonomous real-time navigation system, Restore-L has algorithms, sensors, and a processor helping it find its way, using its multifunction tools and dextrous arms to grab, refuel, service, and relocate.

Curious about the role of AI in space exploration? Read our article below:

Robotics in manufacturing

Industry 4.0 is using robotics and AI to improve processes in manufacturing. From simple algorithms programming a robot to navigate around a warehouse to complex tasks that need robots to be more intelligent, applications can be separated into three categories:

1. Material handling

Including machine loading and unloading and material transfer, material handling applications need a robot to transport materials or parts between locations. Simple tasks can be picking up a part from one conveyor to another, and complex tasks can be placing parts in an arrangement that the robot has to calculate.

Robots that load and unload parts need to be equipped with a gripper to carefully grasp parts, which has to be specifically designed to match the geometry of the parts.

2. Processing operations

Robots manipulate tools to complete a process on the work part, like spot welding, arc welding, spray painting, and more. In the US, one of the most common applications for industrial robots is spot welding of automobile bodies. Polishing, grinding, and routing are other operations that have robots manipulating tools.

With spot welding, the robot positions the welder against the frames and panels in automobiles, completing the assembly of a basic car body. In arc welding, robots perform this continuous process by moving the welding rod along the seam for it to be welded. Robots manipulate a spray-painting gun over a surface when spray painting, coating the object.

3. Assembly and inspection

Robots are increasingly used in assembly and inspection due to their lower cost versus manual labor. By programming robots, in assembly work, multiple product styles are produced in batches, with the robots being reprogrammed in between batches.

A different approach includes producing a variety of different product styles in the same assembly cell, which needs each robot to identify the product style as it arrives. The robot can then execute its task for that unit.

Robots can also inspect work parts with a sensor, replacing human labor in situations where:

- Operations are repetitive and involve the same basic movements every cycle.

- Operations are dangerous or uncomfortable for workers.

- Tasks need work parts or tools that are difficult or heavy to handle.

- Operations let robots be used in two or three shifts.

Want to know more about AI in manufacturing? Check out our article below:

Robotics in agriculture

Robotics in agriculture could help to lessen labor shortage and worker fatigue, alongside helping with sustainability. This can include the monitoring of plant levels, like nutrients, water, sunshine, and more, to make sure that plants grow to their full potential. It also allows for less waste and less water to be used, with AI learning from the data and improving yield in future harvests.

Robots are commonly used for slow and repetitive tasks, such as:

- Utility platforms

- Phenotyping

- Harvest and picking

- Sorting and packing

- Weed control

- Autonomous pruning, mowing, thinning, seeding, and spraying

Certain applications can be difficult to automate, however, and robotic systems need to be designed to overcome obstacles. In harvesting and picking, vision systems need to determine both the location and the ripeness of vegetables and fruits, which can be even more difficult in harsh conditions - temperature swings, presence of dust, movement created by wind, varying light intensity, and more.

Robotic arms need to navigate difficult terrain and delicately grasp what they’re harvesting, which differs from the process used in manufacturing. The arms need to be flexible in dynamic environments, having enough accuracy to not damage fruits and vegetables when picking them.

And with the demand for food outpacing available farmland, we can expect to see more developments in this sector.

Read more about how AI is shaping agriculture below:

Robotics in smart homes

Amazon’s Astro bot has been on the company’s Day 1 Editions program for a few months now, as a US$1,000 invitation-only system. Amazon has announced its regular price will be US$1,449.99 when the Astro bot is out of the program.

As an Echo Show on wheels, it uses artificial intelligence to autonomously navigate around the home, being your eyes and ears when you’re out and about due to its periscope camera. It also has mics and speakers that help you interact with it in person or remotely.

iRobot, the company that gave us the Roomba, has used artificial intelligence and machine learning for their latest model, which avoids pet accidents and messes - the Roomba j7+. This model has an updated navigation and control software, the iRobot Genius, also launched for compatible Roombas.

Version 3.0 of the software iRobot Genius maps users’ homes and uses machine learning to recognize furniture and “clean zones”.

Follow us on LinkedIn

Follow us on LinkedIn